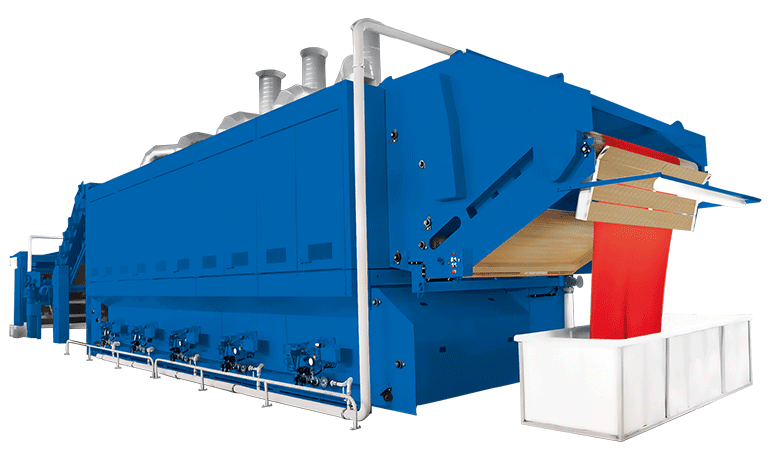

Levelling, steaming and compacting

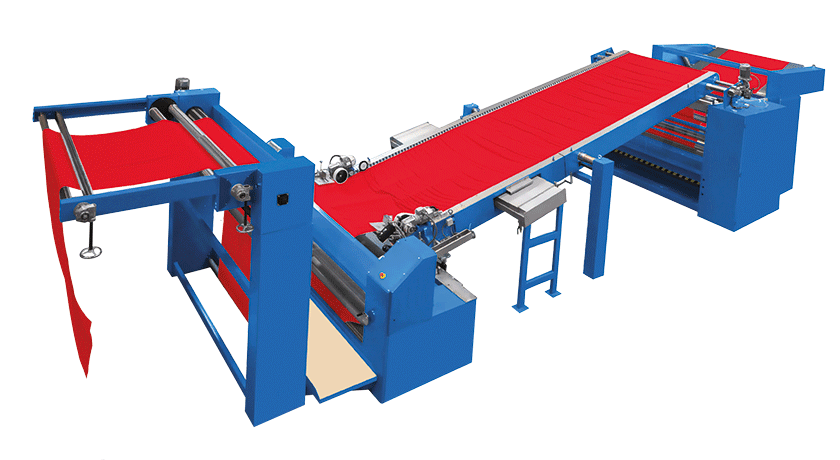

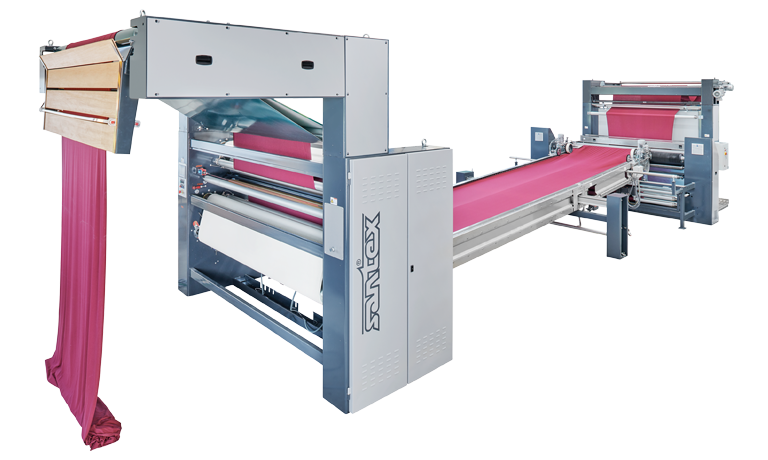

Electronic force measuring rollers are at every regulation position providing total control over fabric tension, extremely gentle fabric handling, and allowing settings to be stored in a recipe for added repeatability.

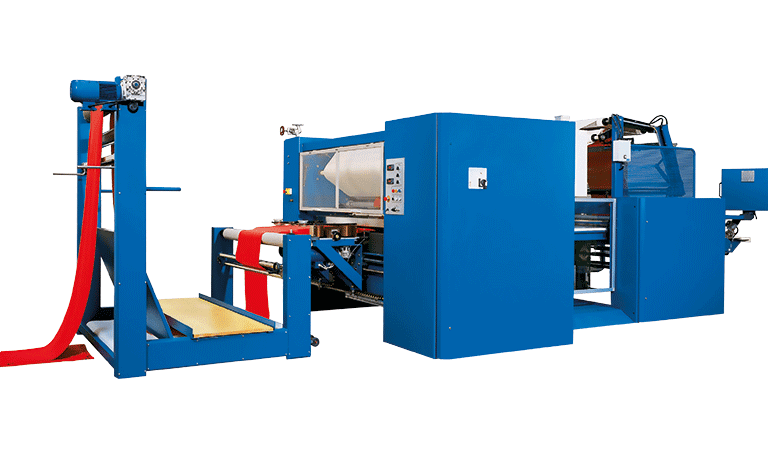

At the heart of the SANTASYNPACT’s incredible performance is how the rubber shrinking unit and specially dimensioned felt compacting unit work together to double both the compacting performance and speed over standard compactors.