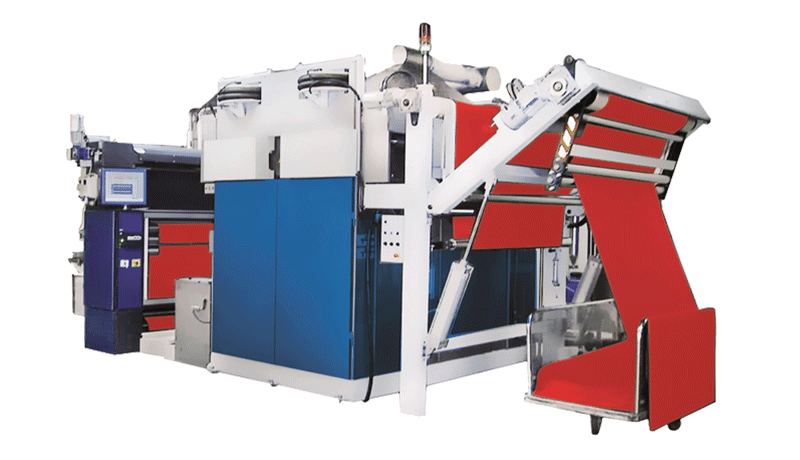

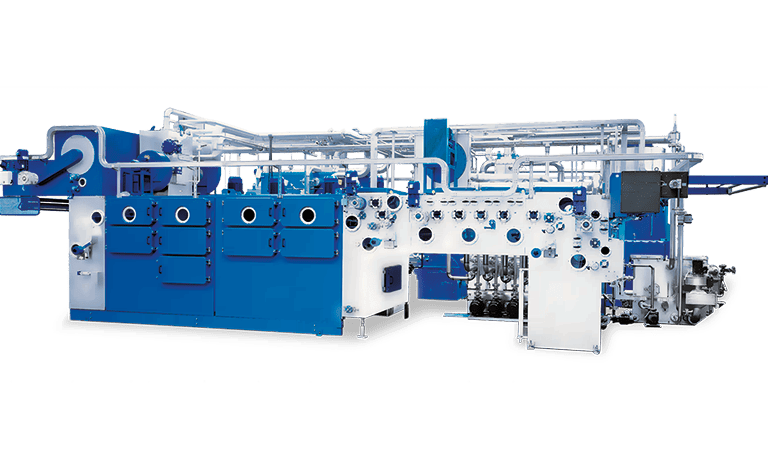

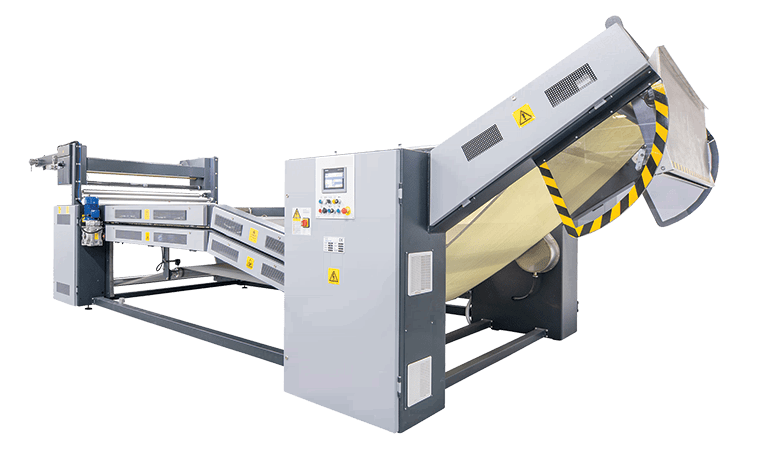

The wool crabbing in continuous by overheated water under pressure

The continuous treatment takes place thanks to the use of special seals positioned at the entry and exit of the machine which allow, by means of a dedicated pump, to pressurize the process area and work at temperatures higher than the ones allowed by the atmospheric pressure.

The combination of working conditions that foresee a fabric that is completely impregnated in water and kept under pressure together with a temperature that is adjustable up to 125° C is the ideal situation in order to reach setting values that are definitely higher compared to any other similar treatment presently available.

The wool fibre turns into a plastic state and the hydrogen and cystinic bonds are broken to be re-shaped under a more stable configuration which is no more only cohesive but permanent such a transformation happens very quickly and the production increase has been calculated in at least 50% more compared to crabbing machines using for example the highly tensioned silicon belts.