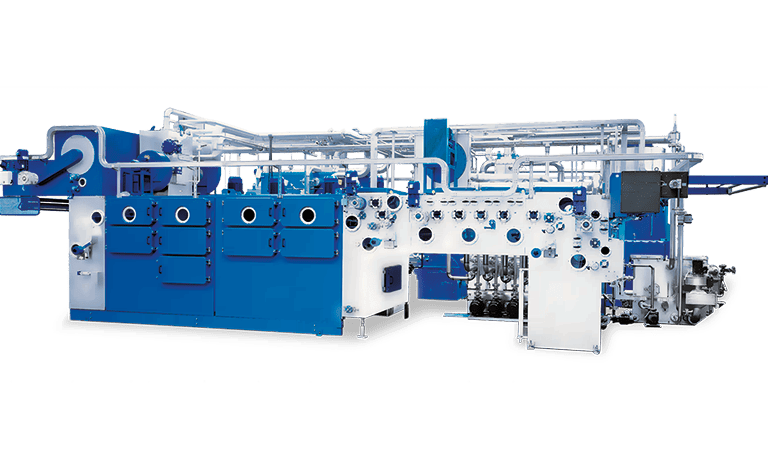

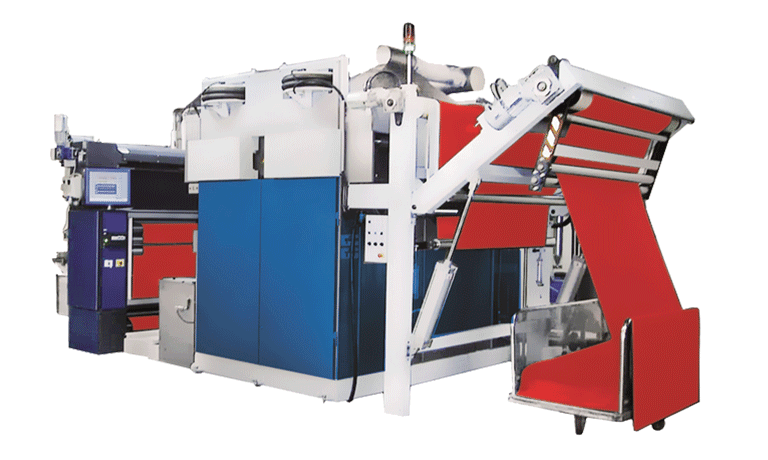

Continuous Decatizing Machine MULTIDECAT 2.0

From the wool sector to the silk one and cotton, for artificial and synthetic fibres as well, particularly when these are blended with natural fibres. Our continuous decatizing machine is equally applicable in the most diverse finishing fields.

It can be used for final decatizing of both woollen and worsted cloth of pure wool and in blends with polyester, viscose, silk, cotton; cotton, linen and their blends, viscose and polyester/viscose blends and pure silk. It can be used for a preparatory treatment to the Kier Decatizing of woollens and drapery articles as well as final fabrics decatizing previously treated by Kier Decatizing, to remove the excess of lustre to soft and to bulk the fabric hand.