Velura

Velura is suitable for the following articles:

•Woven and knitted fabrics made in natural or

man-made fibers.

• Polar fleece for outerwear clothing

• Automotive fabrics

• Single or double face fabrics

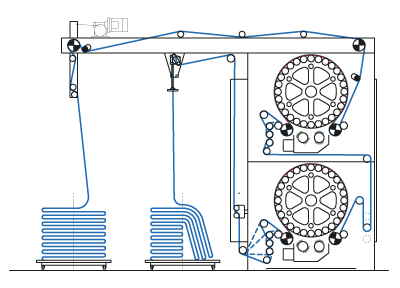

Special care has been given to the fabric tension control. The very short distance among the different parts of the machine avoid any unevenness between the center and the edges thus obtaining a dense full long or short pile.

The machine is equipped with high quality raising rollers driving belts which are more flexible and durable compared to bigger size belts. Five driving

belts for raising rollers drive are provided for the raising rollers drive in order to ensure a full grip and the maximum possible energy transmission

granting a more efficient raising effect.