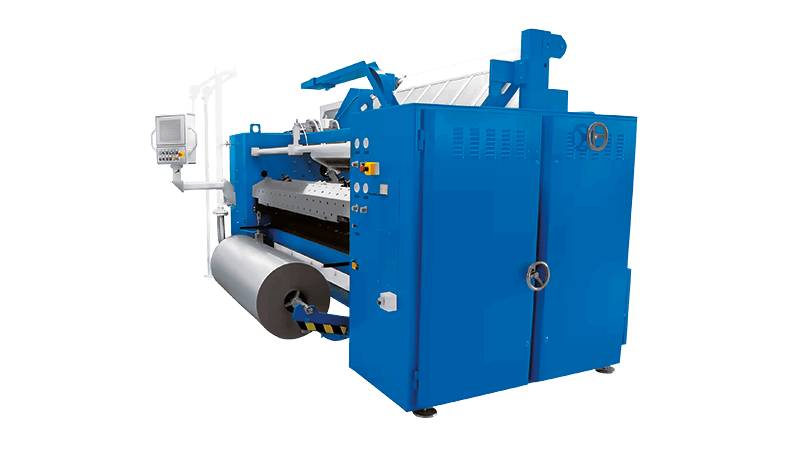

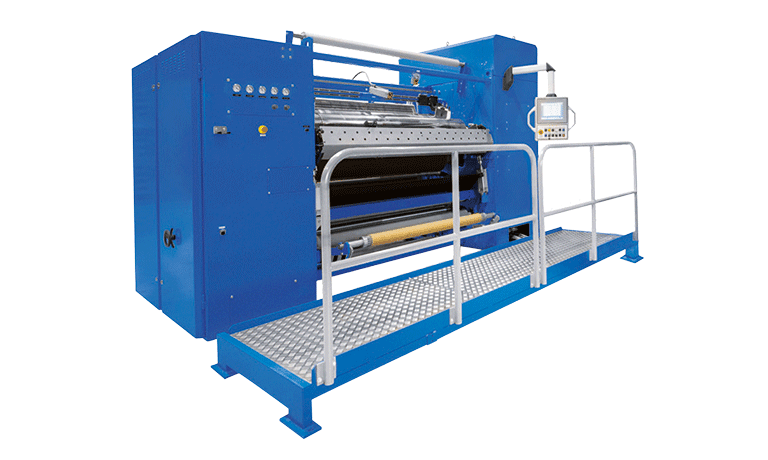

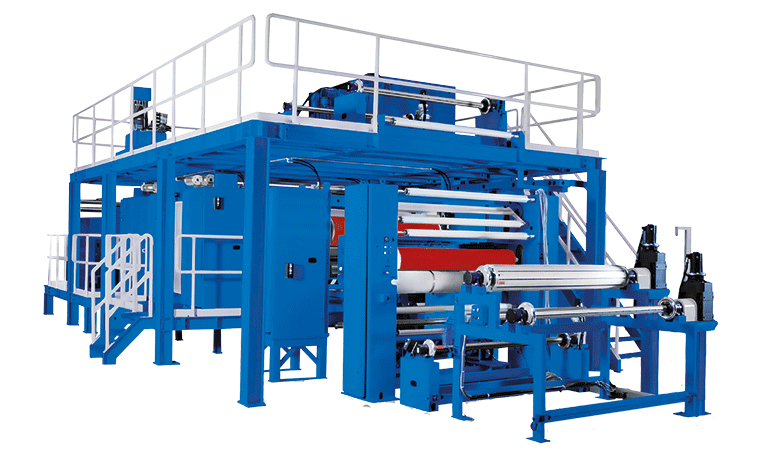

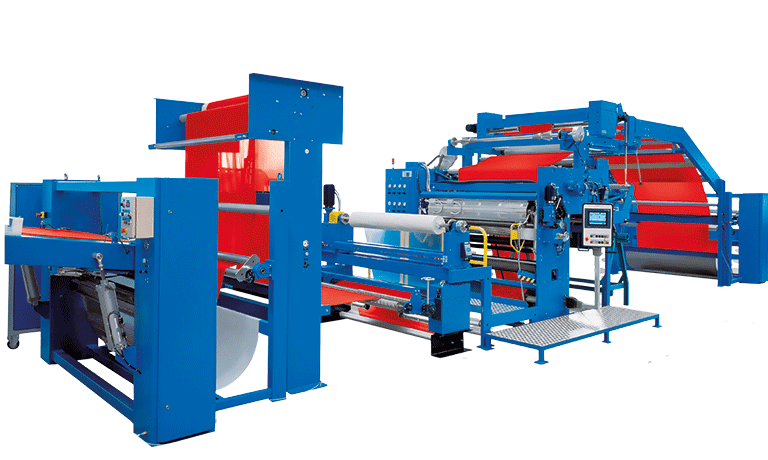

Cavimelt Textile Lamination Machine

The rotogravure system CAVIMELT is the most commonly applied method for lamination. It is a printing system with an engraved roller, in which little cavities are engraved for transfer of the adhesive to the web substrate. Different patterns are available (round dots, pyramidal, nets, lines, etc.) depending on the laminated product.

Using the hot melt process this textile laminating machine applies adhesive as dots or in predefined patterns using an engraved roller on film, web and textile substrates. Both reactive and thermoplastic adhesives can be used. The coating is generally used to laminate additional materials, or to alter the material surface.