The evolution in technical fabrics: resin-coated production

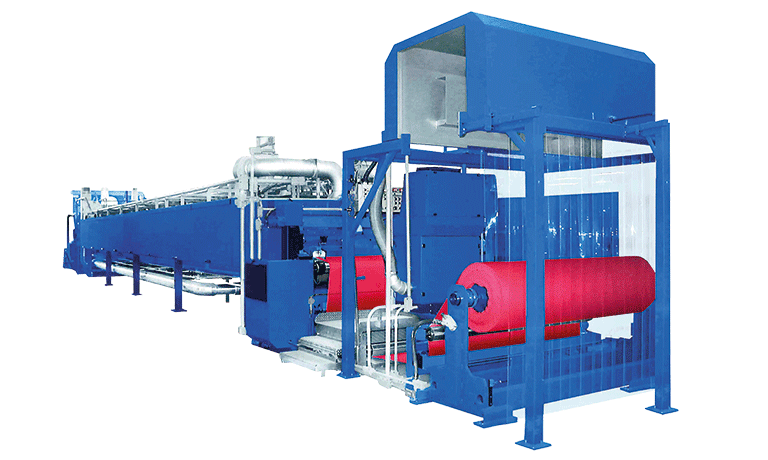

The features of fabrics produced with Isowear change according to the applications, from lightweight resin-coating for special fashion effects, to coatings for technical features as waterproofness, breathability and flame retardant effect.

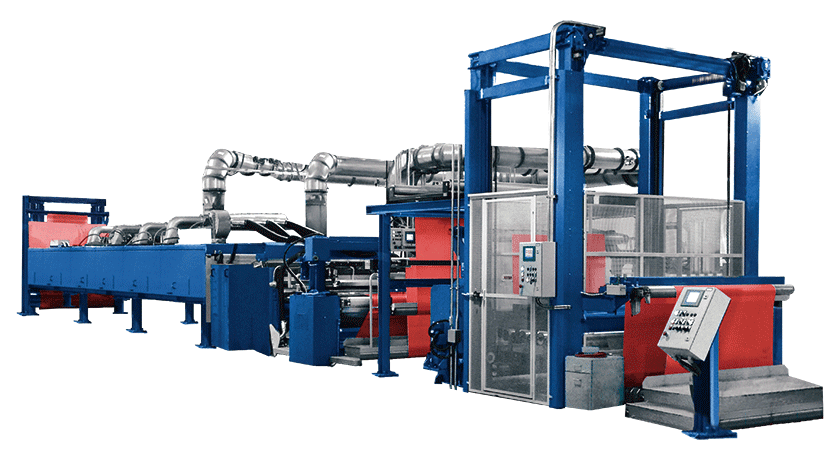

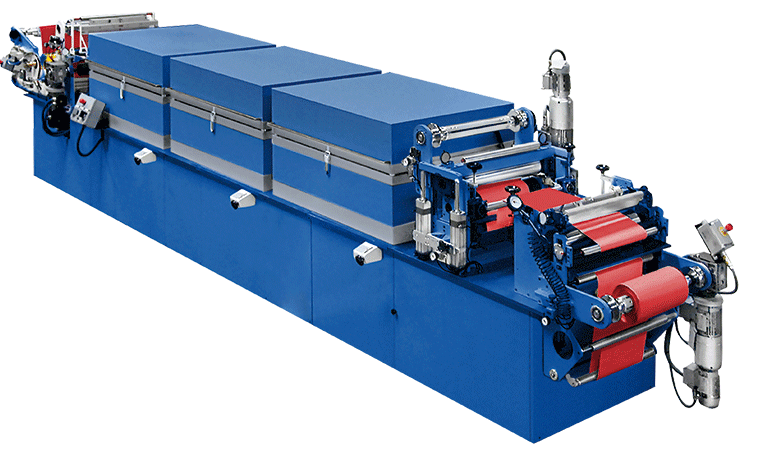

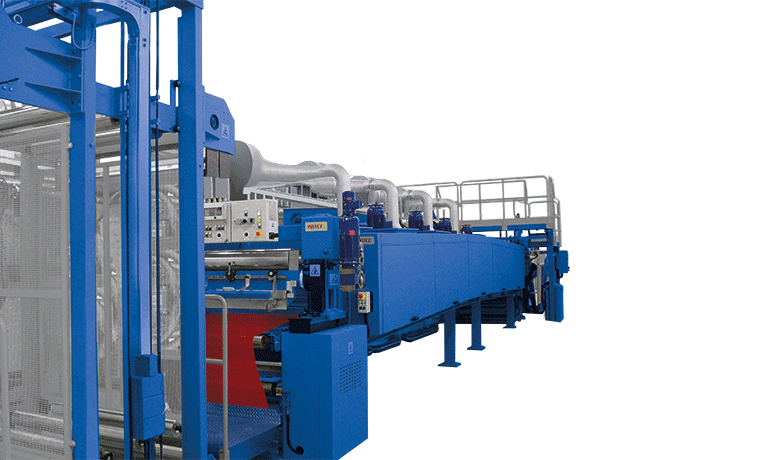

The lines can include different coating systems, impregnation, embossing and lamination. Products for the fashion industry may combine technical features with different surface effects and printing.