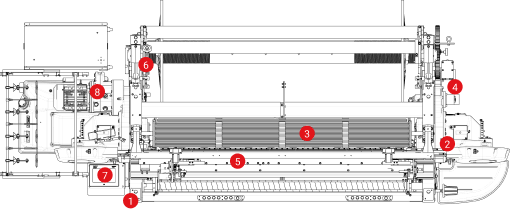

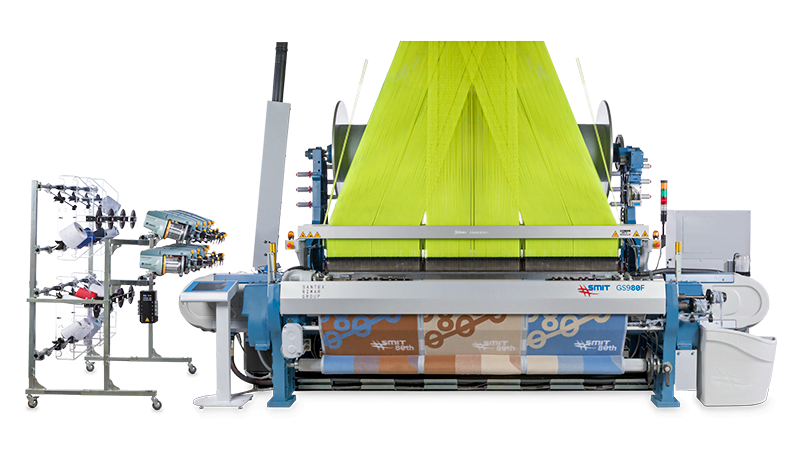

Exceeding 800 rpm 2Fast is the fastest free-flight rapier loom in the world.

2Fast is designed and manufactured in Italy and it was globally premiered at ITMA Barcelona 2019 and struck the attention of the most advanced fabric manufacturers.

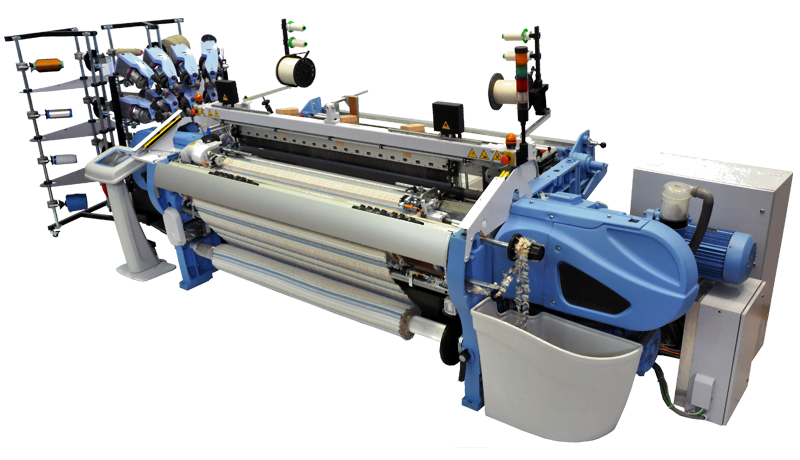

The “Robust Design” methodology guarantees the longest machine life and the lowest spare parts consumption.

FAST AND EASY!