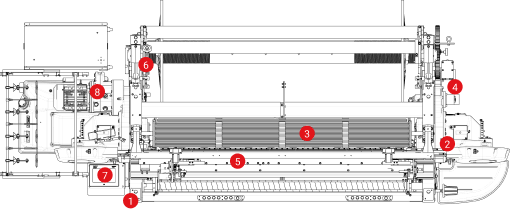

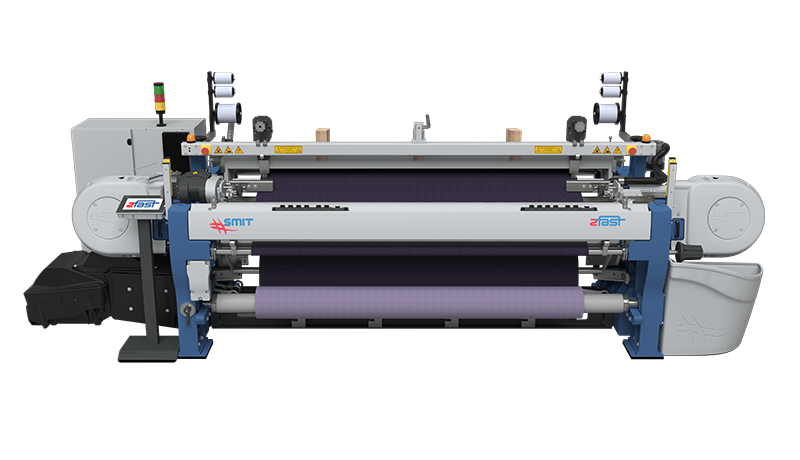

The weft insertion performed by a single rapier and the numerous improvements in mechanic and electronic groups increase the already high quality standards. The ONE modularity concept integrates an extensive variety of arrangement options.

Thanks to the dynamically controlled flexible tape rapier, that ensures excellent performance in all reed width range – from 140 up to 220 cm – ONE shows evidence of extreme versatility. Three different solutions of fancy beam are available, with beam flanges diameter up to 1000 mm.