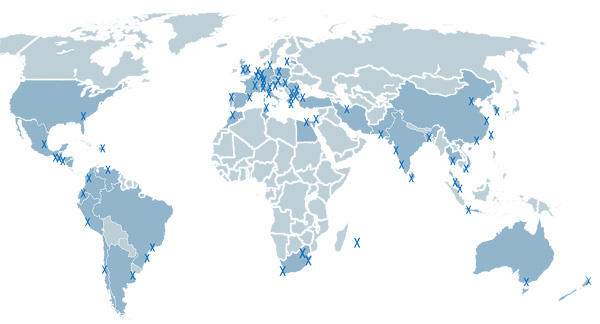

Globally recognized as a forerunner in weaving technology, SMIT is an Italian manufacturer of weaving machines established in 1938 and renowned for its high standard levels of innovation, productivity and versatility, ensuring competitiveness throughout a large variety of applications.

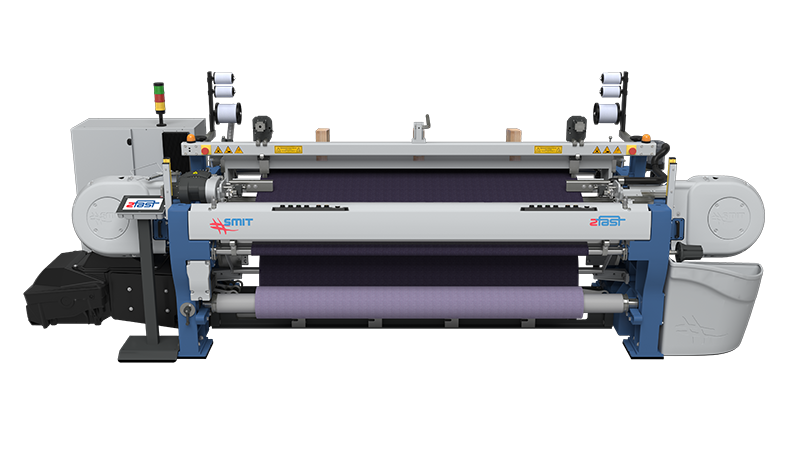

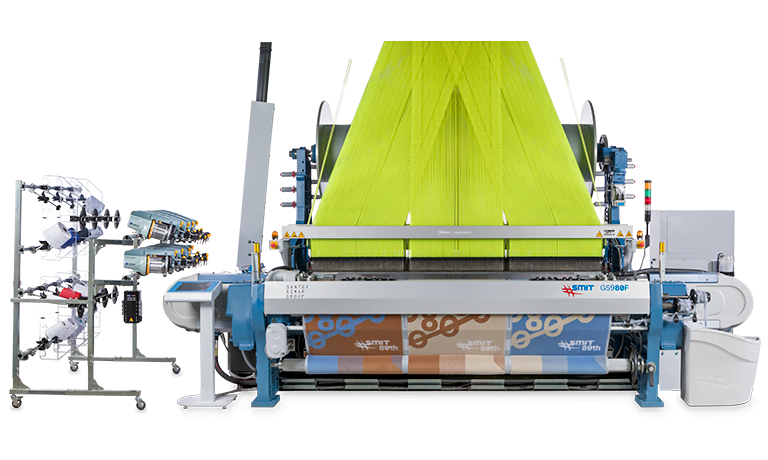

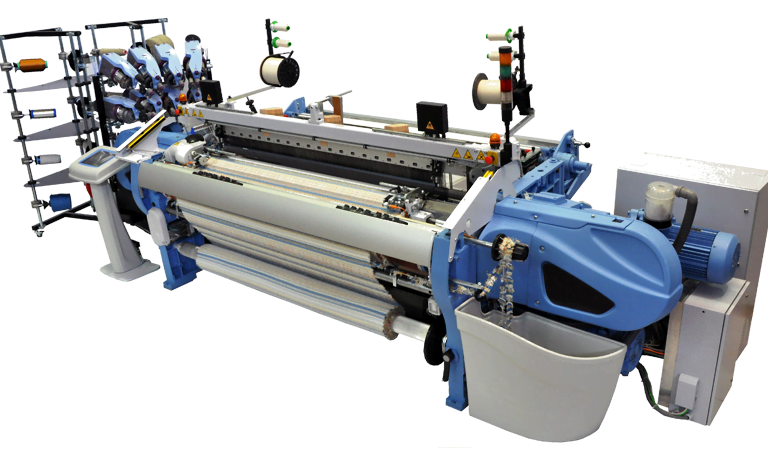

The technology characterizing SMIT product range includes weaving machines with rapier weft insertion for home textiles, garments, terry towels and customized solutions to produce special technical fabrics.

SMIT Smart Platform is a structural architecture concept involving the whole machine project – mechanics, electronics and communication systems – to provide the most advantageous weaving machine configurations to produce high quality fabrics for any sector, widening weaver’s market access.

Modularity concept integrates an extensive variety of arrangement options.