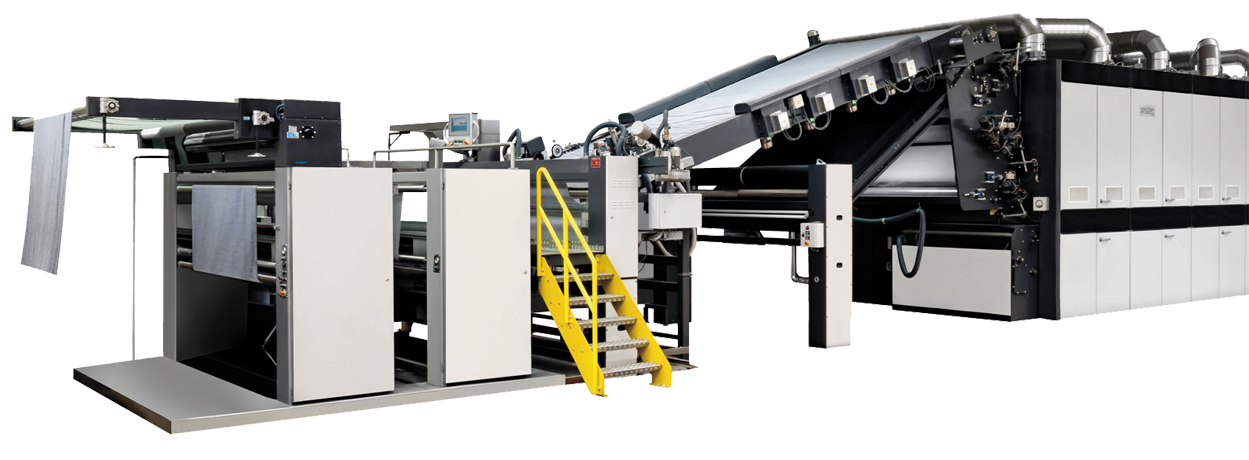

Santashrink Super Jumbo: high-speed textile dryer with low production costs

The Santashrink is made in Switzerland and featured on a modular basis: each dryer chamber is 2 m long with working widths varying between 1800 and 3400 mm. It works on three levels, equipped with upper and lower conveyor belts each. Every level presents specially conceived nozzles in order to guarantee the most effective airflow and airspeed through each step of the drying process. The system works in an optimized balance between required electrical and thermal energy and production output. By this means the drying capacity on one side and the energy input on the other side, lead to high productivity figures and extremely low drying costs/kg fabric. This produces an energy savings of around 35% against many other relax dryers in the market.