Coating for synthetic leather applications

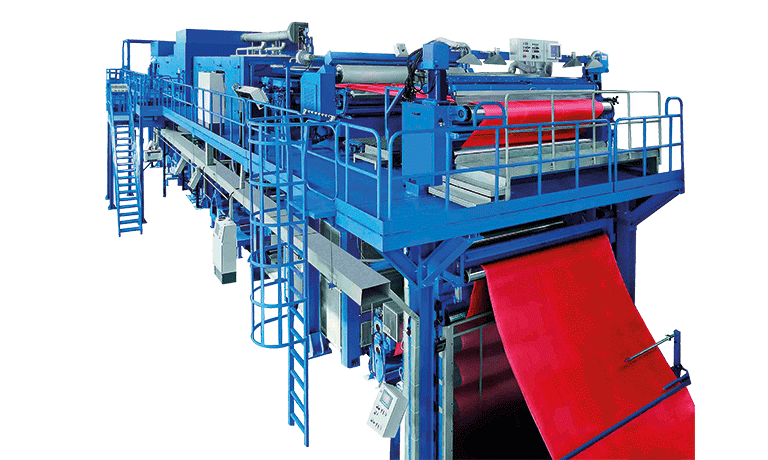

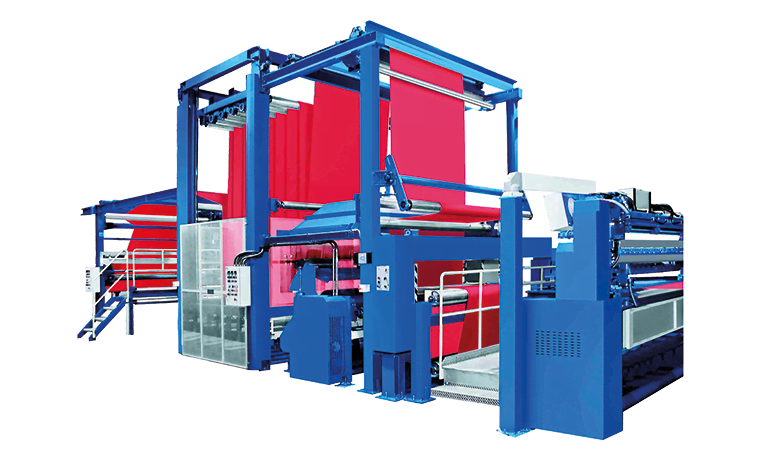

The products can combine high technical features with aesthetical standards with optimal surface finishing effects.

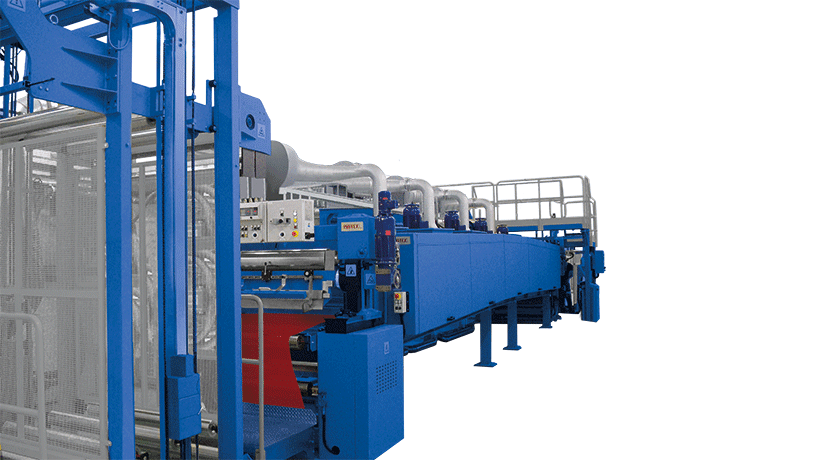

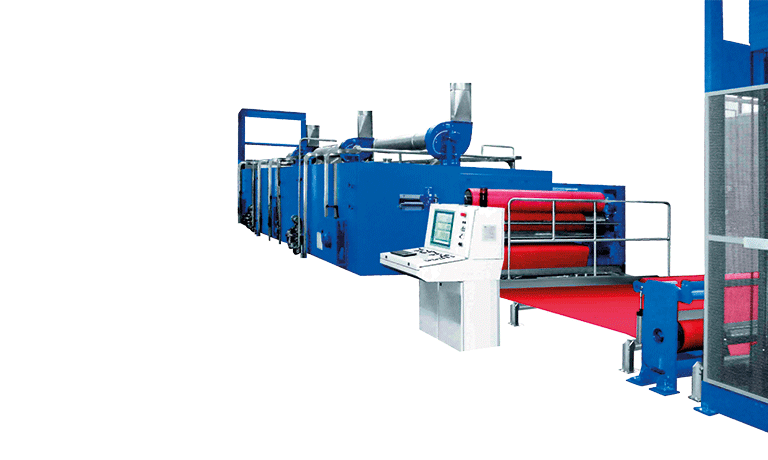

Isoskin lines are customized to meet the customer needs. The lines are studied to reach the highest standard for the range of the chemical products used (PVC, water and solvent base PU, high solid PU).

Customization of the coating lines includes the machines for the production of TPU, engraved rolls units and customized solutions for lamination.