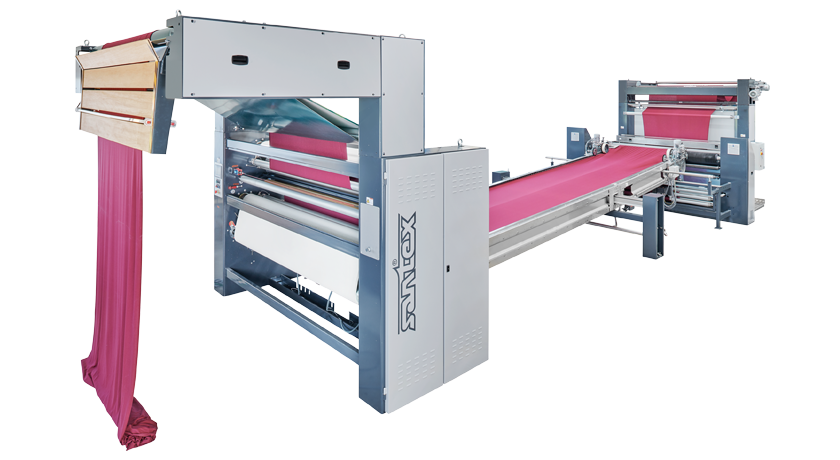

Levelling, steaming and compacting calander

Suitable for fabrics made of natural and man-made fibers it provides the minimum possible residual shrinkage values in the compacting zones and delicate handling of fabric through the machine.

The SANTACOMPACT RD provides the best dimensional stability for the finishing of high Quality open-width knitted fabrics.

Suitable for fabrics made of natural and man-made fibers it provides the minimum possible residual shrinkage values in the compacting zones and delicate handling of fabric through the machine.

Main Features

Working width: 2400 mm others on request

Total width: working width + 1,7 m

Machine speed: 50 m/min

Working speed: 35 m/min

Power supply: 70 kW incl. options

Options: Additional moistening device, automatic weft straightener, edge gumming and drying, edge cutting and selvedge extraction, automatic width measurement, inspection table and winding unit, cooling unit, J-Box, batching winder

Length: approx 14 m

Using data collected by textile machines sensors, ATHENA software system defines the parameters of the STANDARD PRODUCTION QUALITY. Discover all Athena’s advantages.