Dewatering and overstretching / wet on wet impregnation

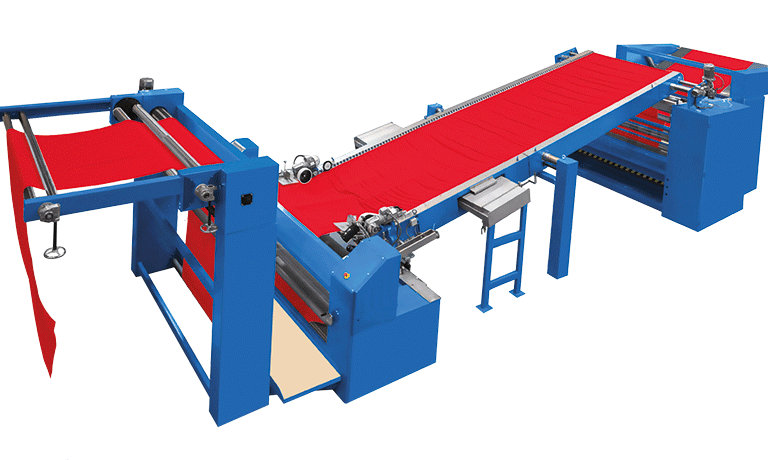

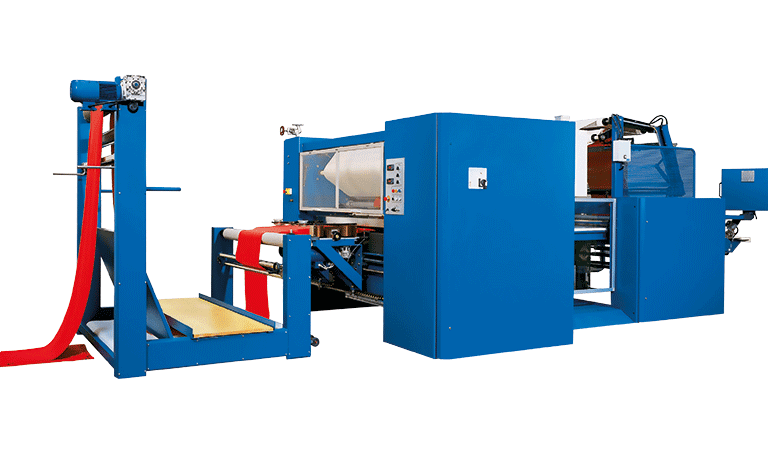

The process of hydro extraction and folding of tubular knits is quite frequently used as a combination of machines, comprising a centrifugal hydro-extractor or also a simple squeezing extractor with a wet-plaiting machine.

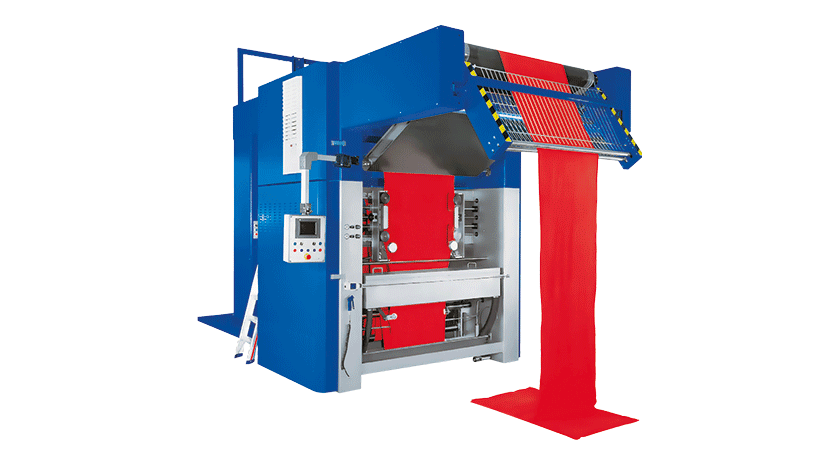

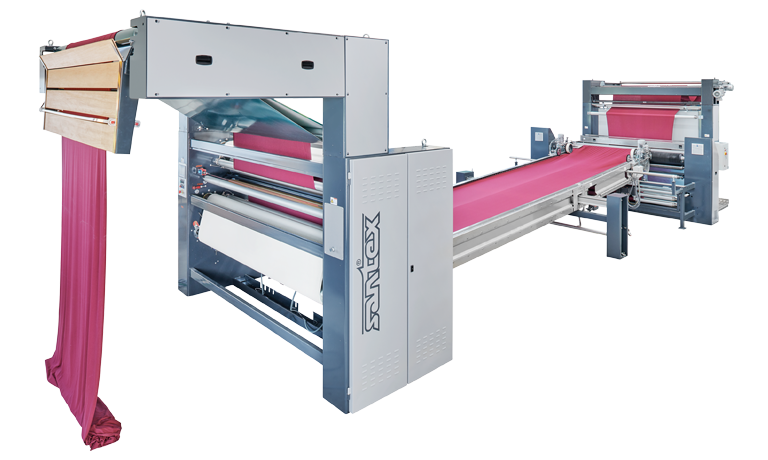

Centrifuging causes creases and wrinkles. These experiences in the practice induced Santex to develop the extracting and over stretching machine known as SANTASTRETCH. This modern machine can open, unravel, extract, over stretch and wet-compact the knitted fabric continuously in one single operation. SANTASTRETCH not only solves the problem but also brings two semi-continuous operations into a single, continuous processing step.