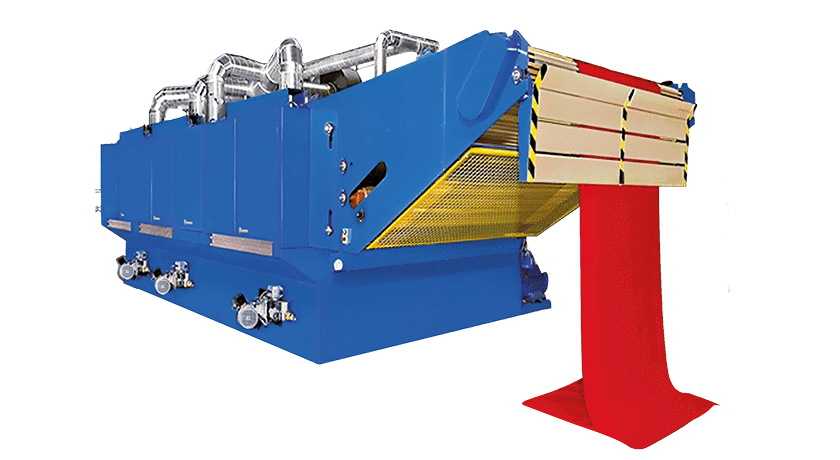

Tensionsless drying, shrinking and relaxing

The technically and economically future-oriented design of SANTASHRINK brings a number of application advantages for the operation, which show up in excellent textile results.

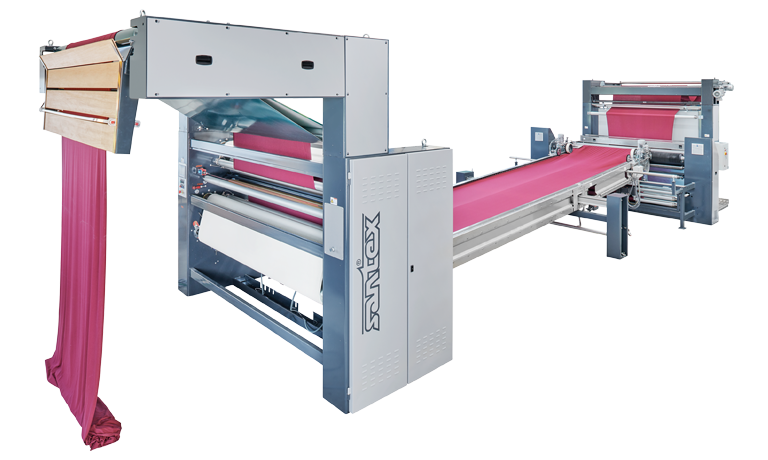

SANTASHRINK is used for the shrinkage, relaxation and tensionless drying of tubular or open-width knitted fabrics. The fabric guidance, wether single, double or multiple strand is effected at one treatment level.

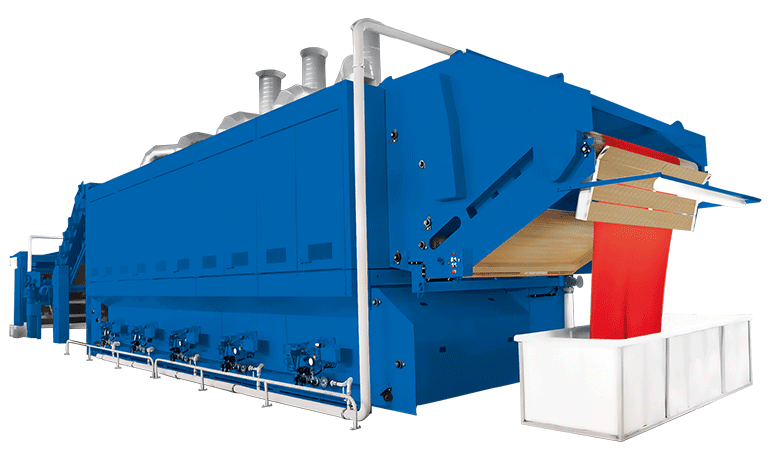

Prior to the last treatment chamber, the fabric passes through a steam and vibration section, which helps to enhance the fabric volume and soft fleecy handle.

Nozzles with large volumes of air enable the water to be heated very quick to the evaporation point.