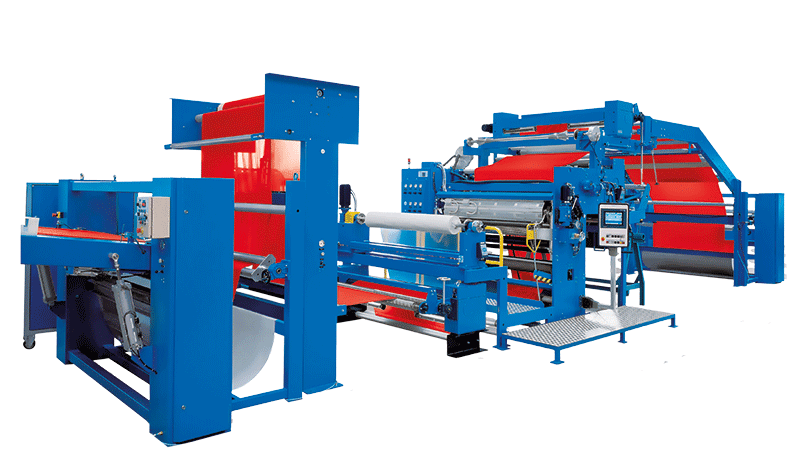

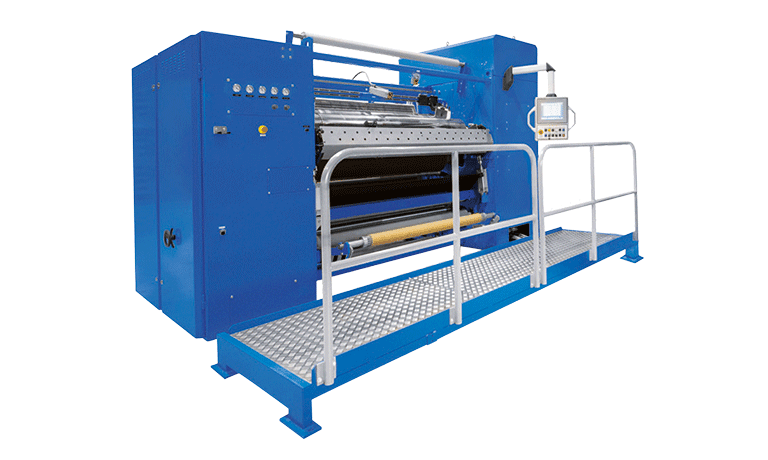

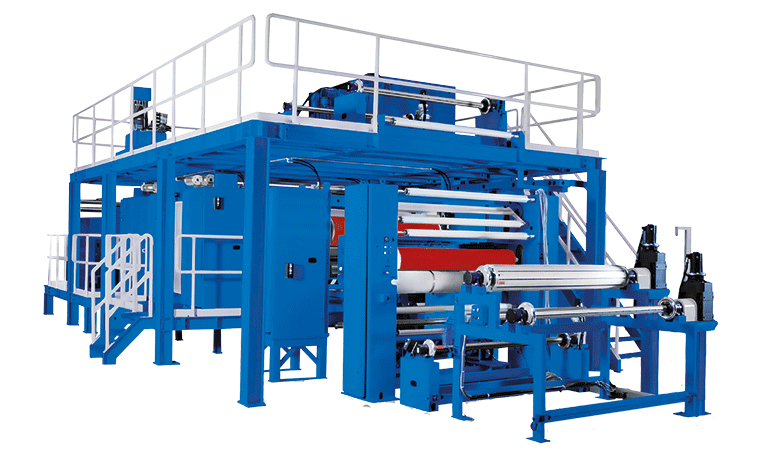

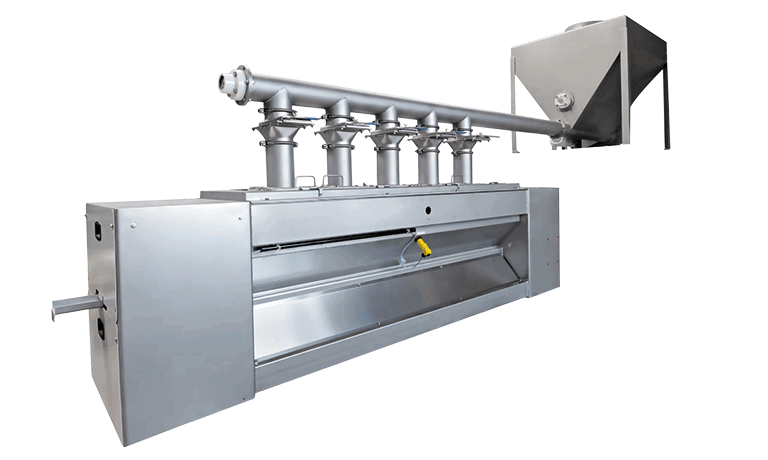

Caviflex Engraved roller machine for adhesive applications

A modular system which allows a quick change between four different systems: engraved roller, screen, slot nozzle and multi-roll.

This enables a wide range of adhesive applications from dot to full service coating, using both reactive and thermoplastic adhesives.

It has the first machinery which offers the possibility to operate in four different Hotmelt Coating Technologies in the same laminating plant.

Auxiliary equipment for heating, cooling, melting (extruder, drum or block melter, …) complete the scope of supply.