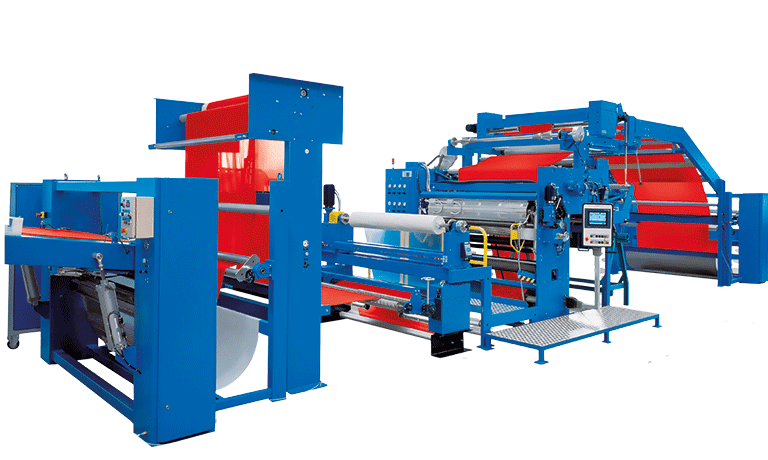

Hot Melt Adhesive Coating Machine

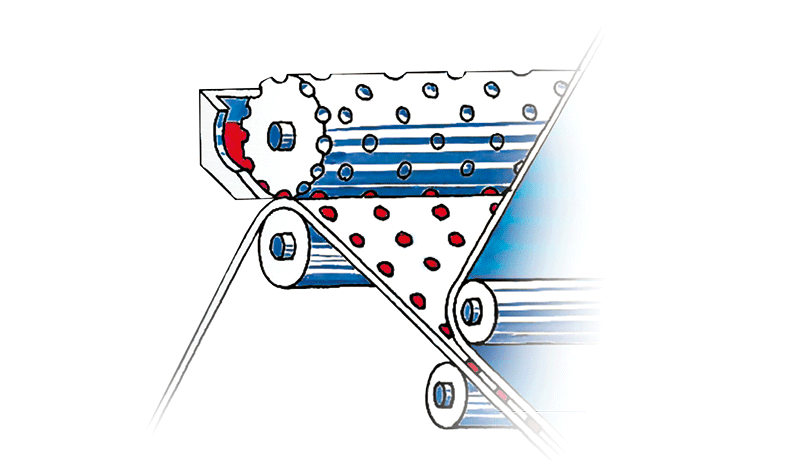

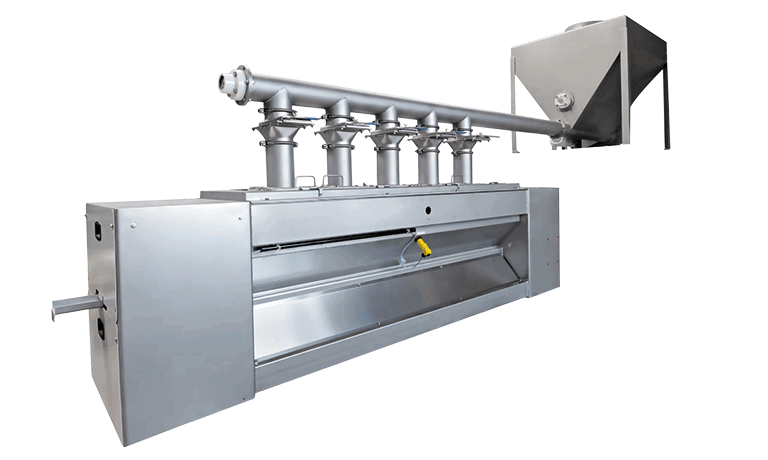

Hotmelt are applied onto a substrate material such as woven, knits, nonwovens, foams, membranes, films, nets, silicon paper, etc. in hot plasticized state.

There are applications where material is only coated for changing the surface of the material, but more often the purpose is to bond or glue two layers of material together to build a composite material, a laminate, hence, the bonding process is commonly called lamination.

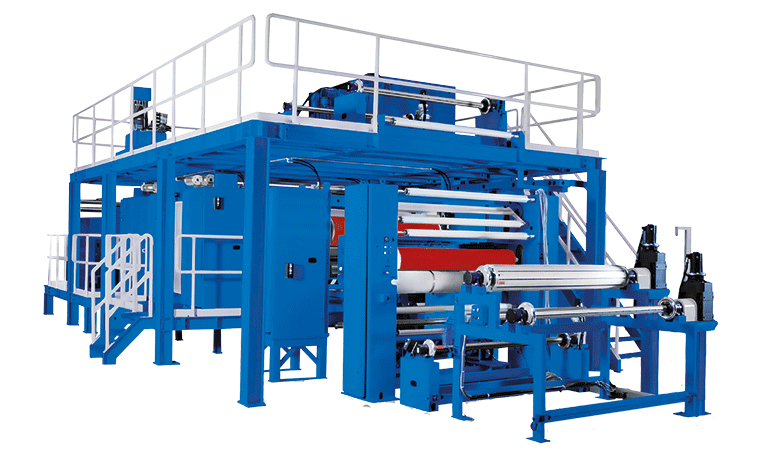

All hot melt machine plants are equipped with low tension web transport drives and tensions are measured with load cells and dancers. Control system can be regulated according to the setpoints. Several web guiding systems ensure a proper alignment of the web layers for coating ad lamination. Accumulators (J-box, roll and belt) ensure an on-going process with no stop during batch changes.