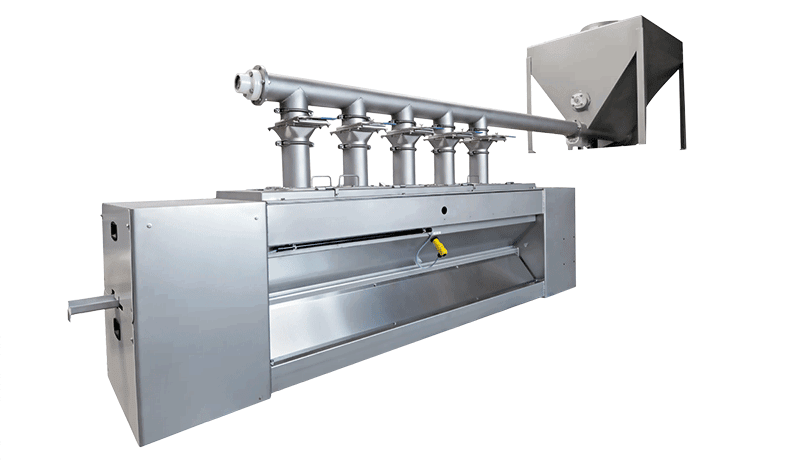

Caviscat Scattering system

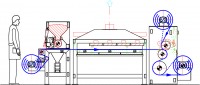

The grift is fed either manually or with vacuum or screw feeders into a funnel shaped trough. These scatter coating units can be delivered also as complete plants. A scatter roll rotating underneath the trough is conveying the product to be scattered to an oscillating brush, where it is evenly scattered via an oscillating sieve onto the underneath moving web material.

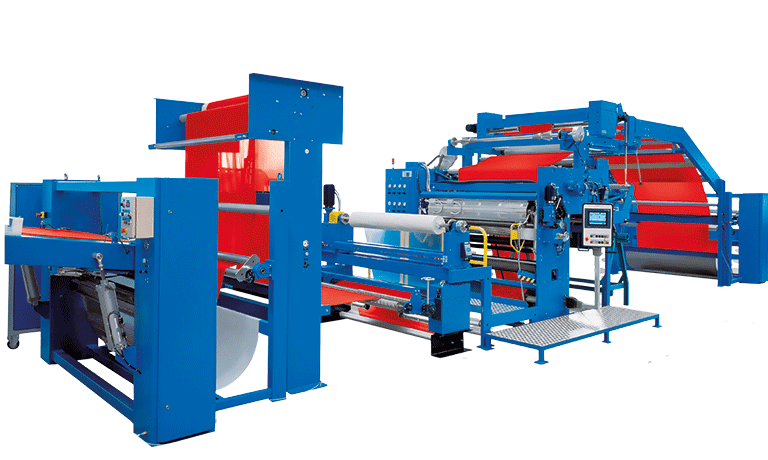

The scatter quantity is determined by the type of the needle roll, its rotating speed, and the web velocity. Complete coating and laminating lines with scattered coating or adhesive material. CAVISCAT scatterers are units for scattering of various web material with free-flowing grit.

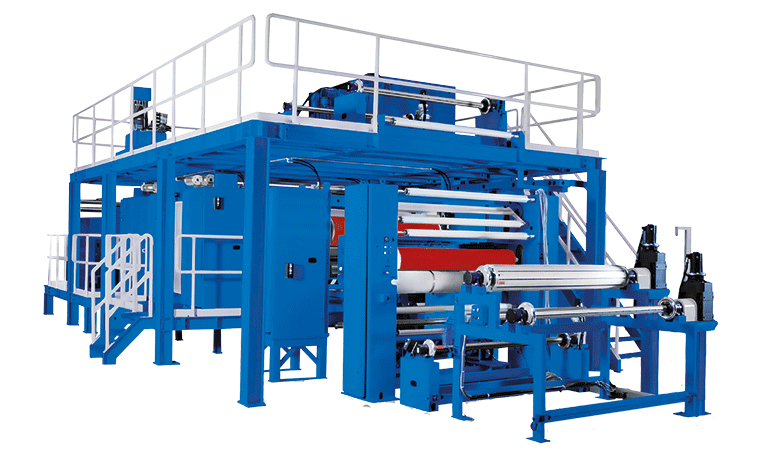

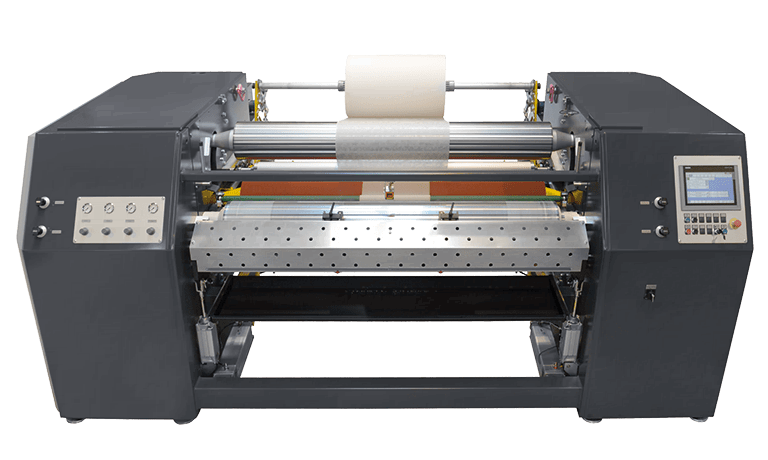

The scattered thermoplastic grit (powder) is sintered under heat and therewith connected to the base material web. Infra-Red fields or Radiant technology is applied for heating. In case another layer is to be laminated on, it is fed to the calendar and there bonded by the molten adhesive to the base layer.