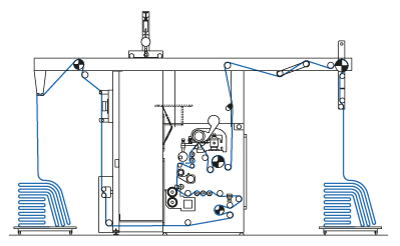

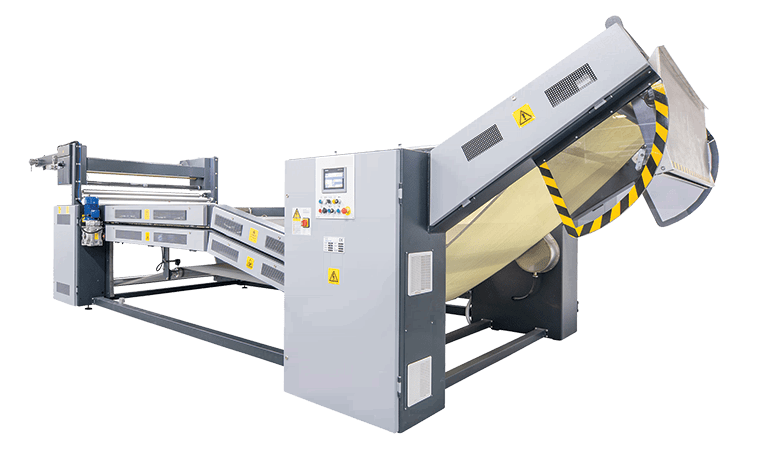

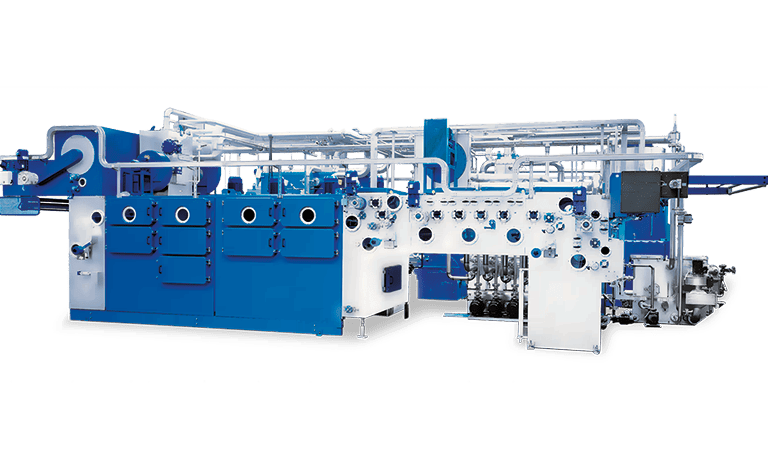

Single and double head Shearing Machine

The fabric tension is managed by electronic loading cells.

Pneumatic pistons lift the shearing cylinder smoothly for an easy maintenance.

Shearing cylinder speed control by means of an AC driven motor controlled by inverter. Revolving speed adjustable from 600 to 1500 rpm. Automatic reverse motion of the fabric at machine stop to prevent shearing marks.

Specially designed suction hood placed on top of the shearing unit complete with a powerful Suction Plant to grant 100% dust removal form the sheared

fabric.

Impregnated merinos felt placed on top of the shearing cylinder for a long-lasting lubrication. All motors on the machine are inverter driven with

adjustable speed settable from the touch screen control panel.

A precision measurement system can ensure the cutting precision of 0,02 mm adjustment gauge between the blade and the fabric measured by a dedicated instrument.

Specially designed inlet to avoid creases formation.

Driving and braking rollers located next to the shearing cylinder provide the correct tension to the fabric through electronic loading cells.