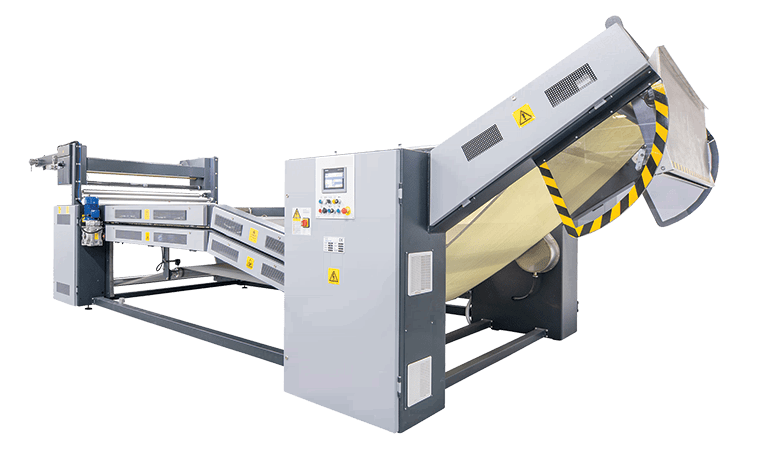

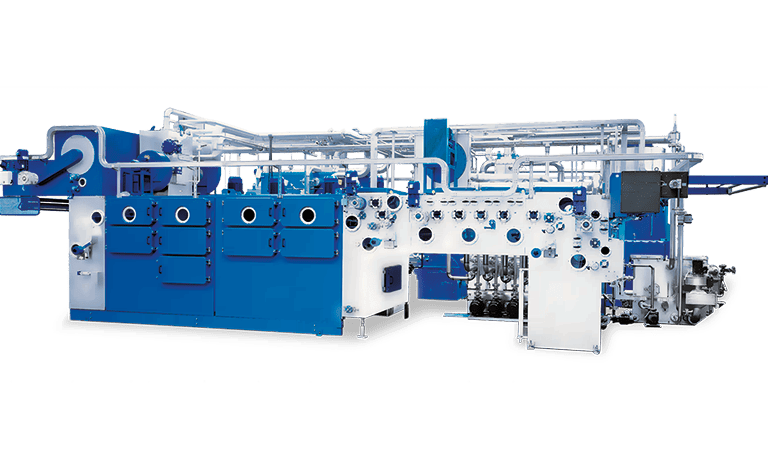

DECOFAST 4.0 matches fashion requests always looking for new fabrics, articles and final finishing effects

It meets the increasing demand of continuous decatizing treatment which, beside the traditional range of worsted and woollen, is enlarged to knit and woven made with a wide number of compositions and blends, ranging from cellulose to synthetic fibre.

The basic machine configuration presents an accurate fabric tension control and management, very effective especially when treating elasticized fabric woven or knit as well.

Compared to Decofast the machine, in knit configuration, foresees an inlet studied and developed with effective and accurate devices for fabric tension control and selvedge opening. The more compact machine size improves accessibility on both lateral sides to ease the maintenance activities. Innovated felt with new characteristics assure an even and uniform fabric aspect, to reduce the steam consumptions and increase the working life of the felt itself. The friction of mechanical elements in contact with felt is minimized. The vessel steam pressure has been enlarged with possibility to reach three bars.

Electric, electronic and software parts are renewed together with drive motors of high precision performances. While electrical components are highly reliable, maintenance and parts substitution is simplified.