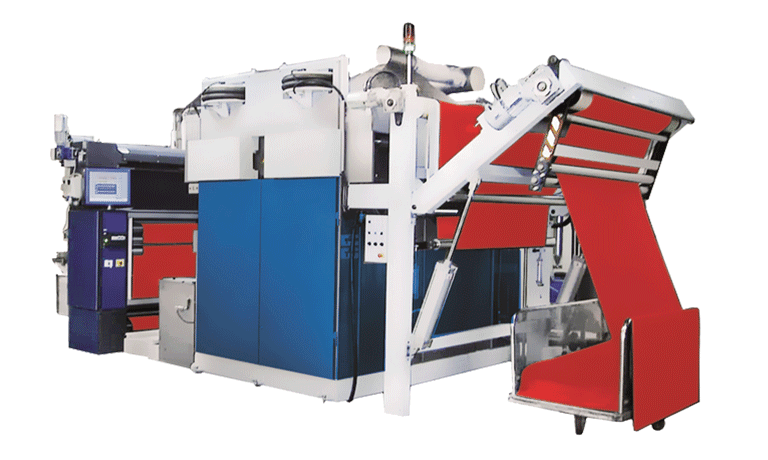

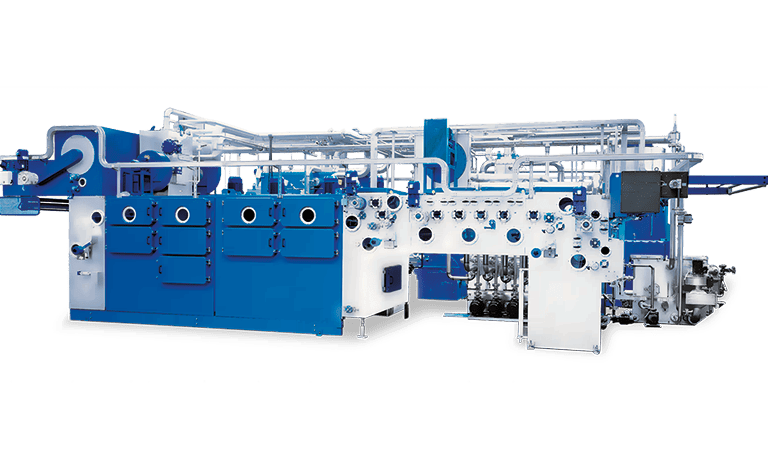

Steaming and compacting of tubular fabrics

The knitted fabrics coming completely relaxed from the shrinkdryer can be guided to the SANTASPREAD steaming and compacting calender throught a specially designed feeding unit and scray device.

The SANTASPREAD variants facilitate expensive computer aided automation, as well as the final inspection of finished fabrics.