Process

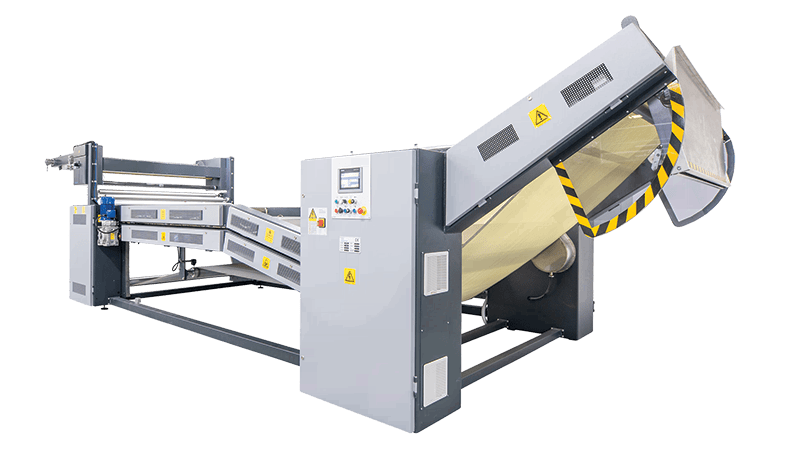

The fabric is guided to the motor-driven feed roller located at the machine inlet where the correct degree of overfeed is assured. The fabric is then placed on a conveyor belt and steamed in the tunnel, which is supplied with the steam via subjacent injection pipes.

The motorized roll, covered with anti-slippery material, lays the fabric on the conveyor belt.

The right degree of overfeeding is assured by adjusting the roll speed.

The adjustment can be manual, by a potentiometer, or automatic by a photocell which detects the fabric position.

The driven conveyor belt transports the fabric inside the vaporizing tunnel. The relaxing and swelling effects of the fabric are provided by the direct steam injected and the belt vibrations. The belt vibrations are generated by a proper roll placed under the conveyor belt. Amount of steam and vibration degree are adjustable, according to different kinds of fabrics and results required.

The quantity of steam is adjusted by means of PLC control while steaming of fabric is effected under absolutely tension-free conditions.

The top of vaporizing tunnel is closed by a series of steam heated panels.

Escaping steam at tunnel entry and exit is trapped and sucked by specific sucking hoods. Heated panels and sucking hoods are to prevent steam condensations which can lead to water drops on the fabric.

The vaporizing tunnel injecting steam nozzles is the results of the long Sperotto Rimar’s research and experience. The special design ensures the uniform and effective passage of the steam through the fabric to achieve the best vaporizing results.

At vaporizing tunnel exit, an inclined conveyor belt transports the fabric to the plaiter (flat or variable displacement according customer needs).

Under the exit conveyor belt is positioned a suction unit to cool the fabric and remove residual steam.

UNIVERSA fabric relaxing machine can be used every time relaxing, shrinking and bulking effects are required: to remove excessive shine imparted to the fabric in previous finishing operations, to relax and shrink the fabric before decatizing treatment (in this case UNIVERSA and decatizing machine can be connected and operate as a textile finishing line).