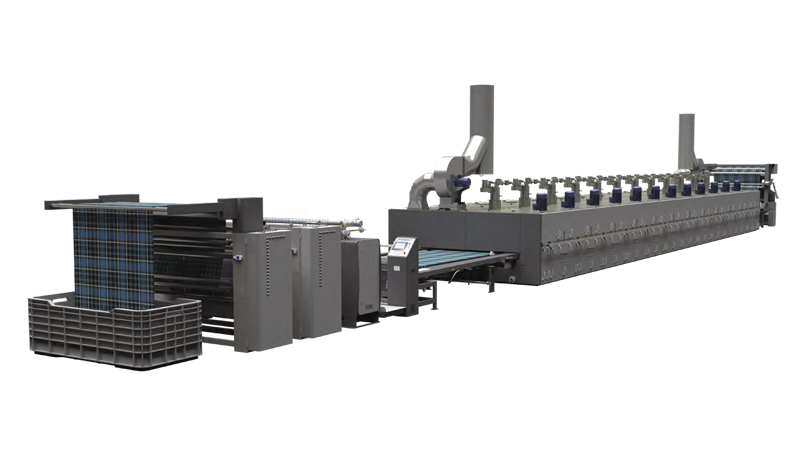

SANTAFRAME: High performance and stenter frame for knitted and woven fabrics

In a wide variety of versions, using a novel air-flow technique: the length of the stenter frame or number of chambers is chosen according to the required drying and/or heat setting/curing capacity.

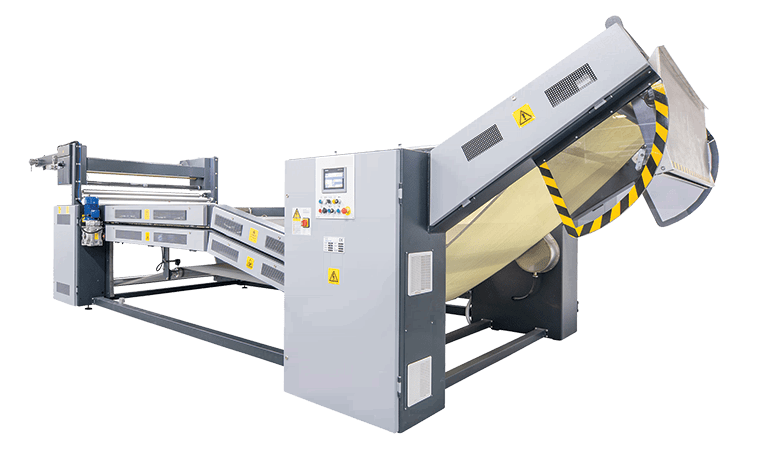

The outstanding performance and production of the SANTAFRAME is based on continual development using the latest advances in thermodynamics, allied to the changing need of customers.

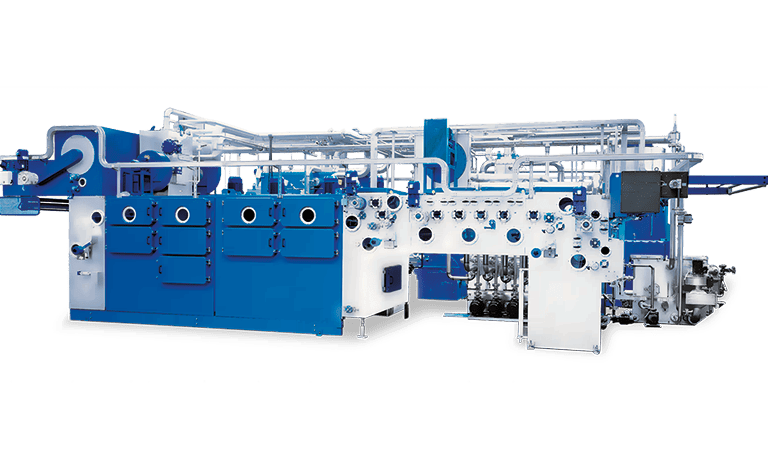

The heating system is located above the fabric track in the upper part of the 2m long treatment zone. Circulating air fan draws the air from the nozzle and treatment zone through the filter panels and directs it along a short path to the heat exchanger, from where it is fed into the nozzles.

A regulating flap in front of the nozzle boxes allows the top and bottom airflow to be continuously adjusted. The arrangement of the heat source on the pressure side of the circulating air fan allows for a high air circulation speed and hence a higher drying capacity.

This leads to energy saving and cost reduction in the drying and heat setting of textile fabrics.