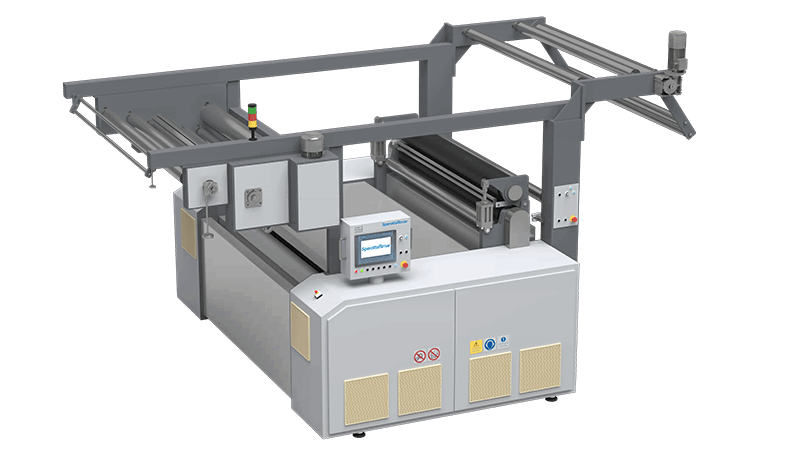

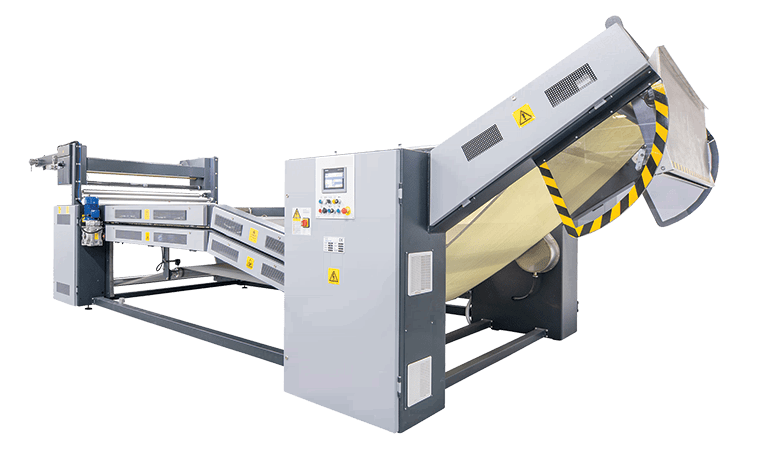

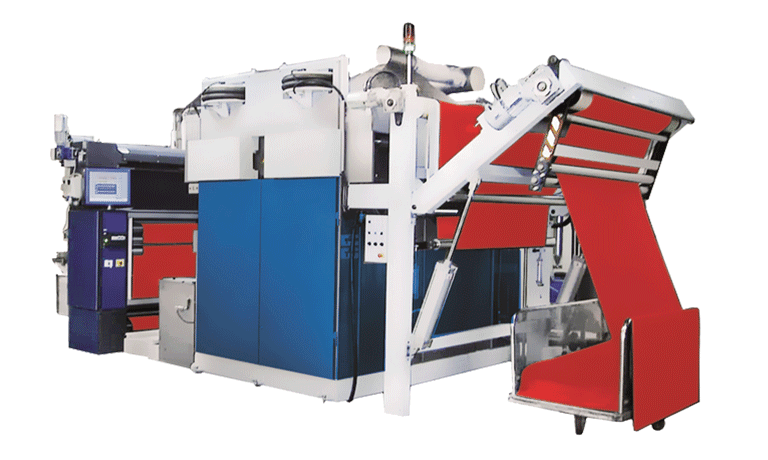

Wet Sueding Machine

In comparison with the traditional dry-sueding process, which leads to hand and surface effects through a partial sueding of the nap and produces amore or less dense pile orientation, the wet-sueding distinguishes itself by achieving the soft surface without any noticeable orientation of the pile.

One peculiar feature of wet-sueding is that the water used in the process acts as a form of fibre lubrication. This increases the sueded surface area on the fabrics, reduces the quantity of removed fibres, gives a shorter fibre appearance with no major reduction in the tensile strength of the processed article.

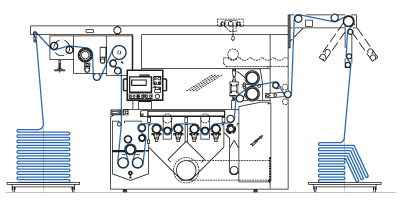

Following the path of the fabric during the particular process, we can see that it is guided from the top into the impregnation tank where it is dipped completely in the water. On leaving this impregnation stage, the fabric is spread and guided into the horizontal sueding area, while its tension is controlled by means of a load cell.